Ensuring Quality of Construction Through On-Site Testing

At Agents of Architecture, we advocate for and specify on-site testing to ensure quality assurance during construction. These tests play a pivotal role in safeguarding the integrity, durability, and longevity of each project. By establishing a collaborative testing framework, we can mitigate risk for all project stakeholders.

Specifying testing aligns the entire project team — designers, contractors, building consent authorities, and clients — toward a unified goal of delivering high quality construction. These tests are integral parts of our commitment to making a positive and lasting impression on the built environment.

Monitoring testing is our commitment to quality assurance and construction integrity.

Key testing that we specify include quality control of weathertightness around membrane roofing - Electronic Field Vector Mapping (EFVM) and aluminium window and door joinery - AAMA 501.2 testing. By undertaking these tests, we proactively mitigate risks associated with potential leaks in roofing membranes and compromises in window joinery systems.

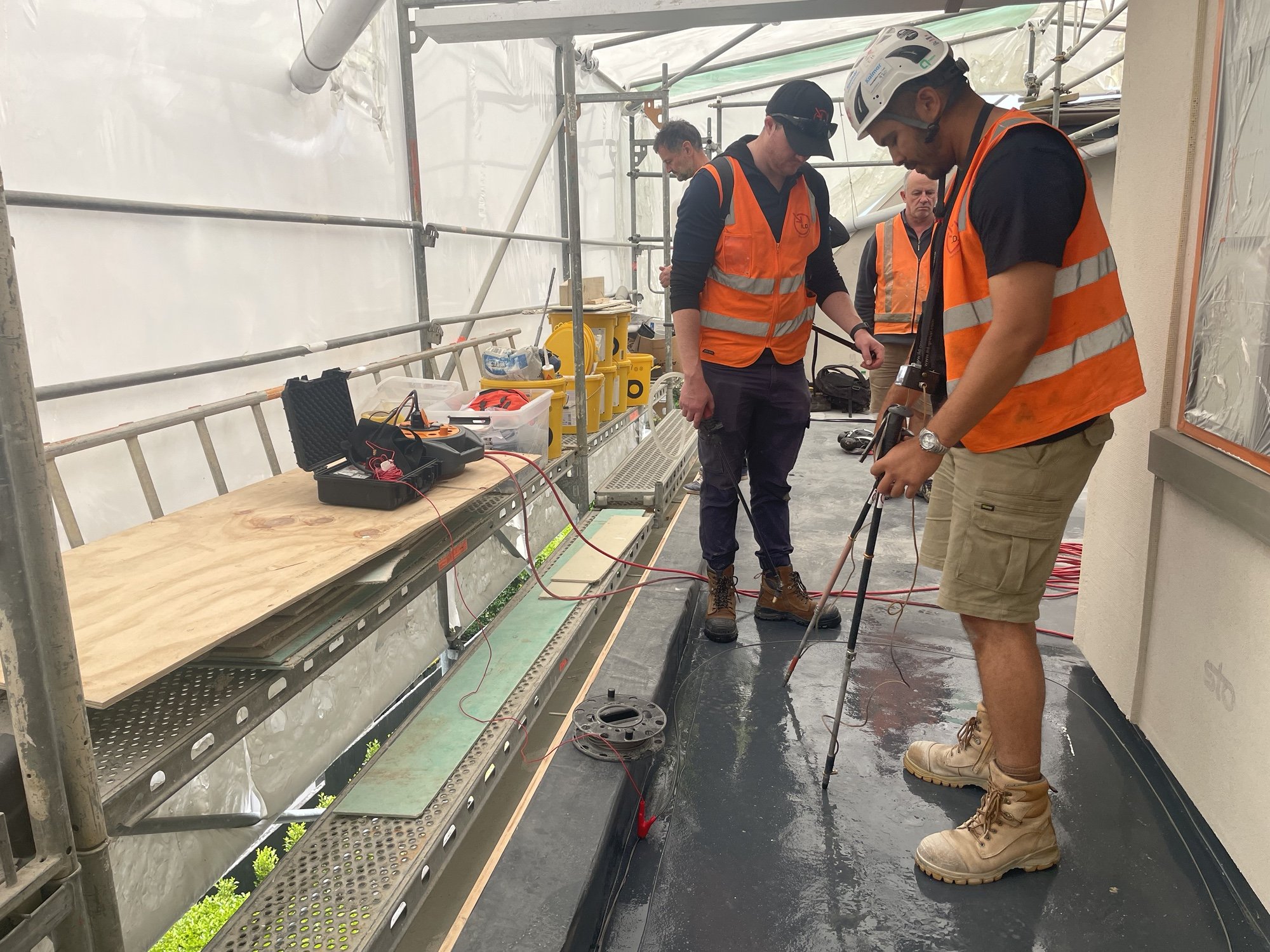

EFVM allows for the early detection of breaches or defects in the roofing membrane. By identifying potential leaks at an early stage, corrective measures can be taken promptly, preventing water ingress and potential damage to the building structure and contents. This non-invasive testing method not only detects leaks but also pinpoints their precise locations. This accuracy is crucial for efficient repairs, minimizing the need for extensive exploratory work to find the source of a leak.

ILD using Electronic Field Vector Mapping to triangulating a breach in the membrane.

AAMA 502.1 joinery testing is essential as it evaluates the quality of workmanship and performance of the joints in window and door joinery systems including curtain walls. This testing ensures that the connections and joints perform and can withstand environmental stresses and can identify potential weaknesses in the joints or premature failure and degradation. By assessing the integrity of these joints, the AAMA 501.2 testing helps verify the durability, efficiency, and reliability of the fenestration system, ensuring it meets industry standards and provides optimal performance in various conditions.

Onsite Window Testing Ltd replicate site weather conditions with a controlled water pressure, even distribution, and distance from the joinery.

Testing is a proactive approach that prevents costly rework, ensures project timelines, and fosters cost-efficiency for all stakeholders. For our clients, these tests are pivotal in safeguarding their investment and ensure that the construction meets industry standards, enhances durability, sustainability, and long-term value.

Specifying these tests exemplifies our dedication to transparency and client education. By involving clients in quality assurance measures, we instil confidence in the project's integrity and our commitment to their satisfaction.

Contractor commitment to testing mitigates their risks and ensures quality construction.

For contractors, these tests signify a commitment to delivering exceptional craftsmanship. It sets them apart as industry leaders, showcasing their dedication to quality, compliance, and professionalism. By adhering to these stringent testing measures, contractors mitigate risks associated with faulty construction. This safeguards their reputation, mitigates potential liabilities, and establishes a track record of reliability and excellence.

On-site testing represents Agents of Architecture’s dedication to elevating industry standards, ensuring proactive quality assurance, and fostering collaboration among all project stakeholders. These tests are more than milestones in a project; they represent excellence in shaping lasting structures and fostering trust among our clients, contractors, and design teams.